Related Post: SEA ME – Sea Algae Yarn / Spider Silk / Siberian Birchbark Trim

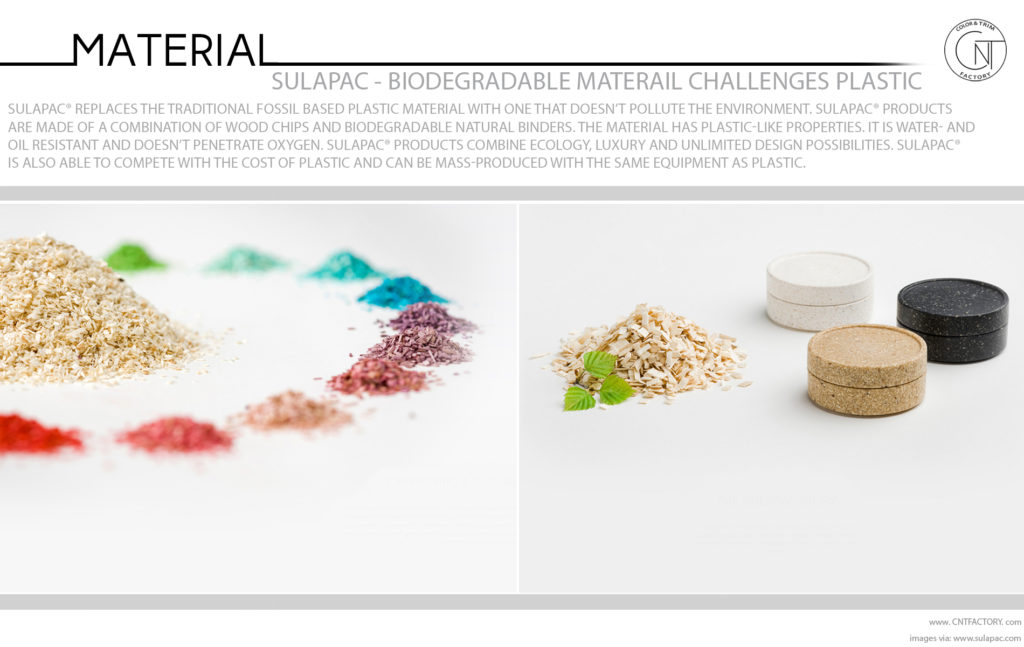

Sulapac® Biodegradable Material Challenges Plastic

Sulapac® innovation is based on Suvi and Laura’s years of study of medical applications and biomaterials. In the research world, they realized that as entrepreneurs they could have a stronger impact on the future of the environment. When the doctoral duo’s biomaterial research was combined with the wood composite expertise of Petro Lahtinen and Antti Pärssinen, Sulapac® material innovation was born.

The business idea was found surprisingly close as both Suvi and Laura had several creams and cosmetic packs in daily use. Cosmetics felt like a natural starting point for the world conquest with new, fully biodegradable packing.

Sulapac® products are made of a combination of wood chips and biodegradable natural binders. The material has plastic-like properties. It is water- and oil resistant and doesn’t penetrate oxygen. Sulapac® products combine ecology, luxury and unlimited design possibilities. Sulapac® is also able to compete with the cost of plastic and can be mass-produced with the same equipment as plastic.

The founders have spent a lot of time developing both the production technology and the brand, researching the target market and drafting their main message. The packaging production required special attention since the wood material must flow smoothly and evenly through the mass without blocking the manufacture equipment. They also sought and discovered the right technology and the best possible ecological dyes for dyeing the wood chips. Nordic design gives the packaging concept its finishing touch.