Sorry, this content is for members only.

Join To View ThisRelated Post: MYLO Mushroom Leather / Leather Gradient / 3D Leather

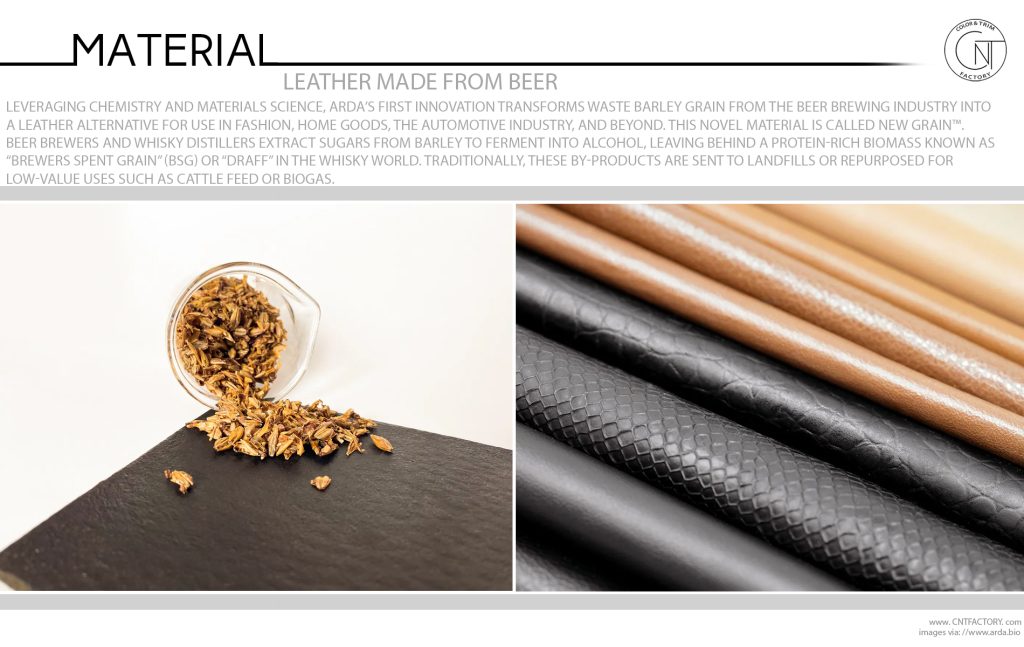

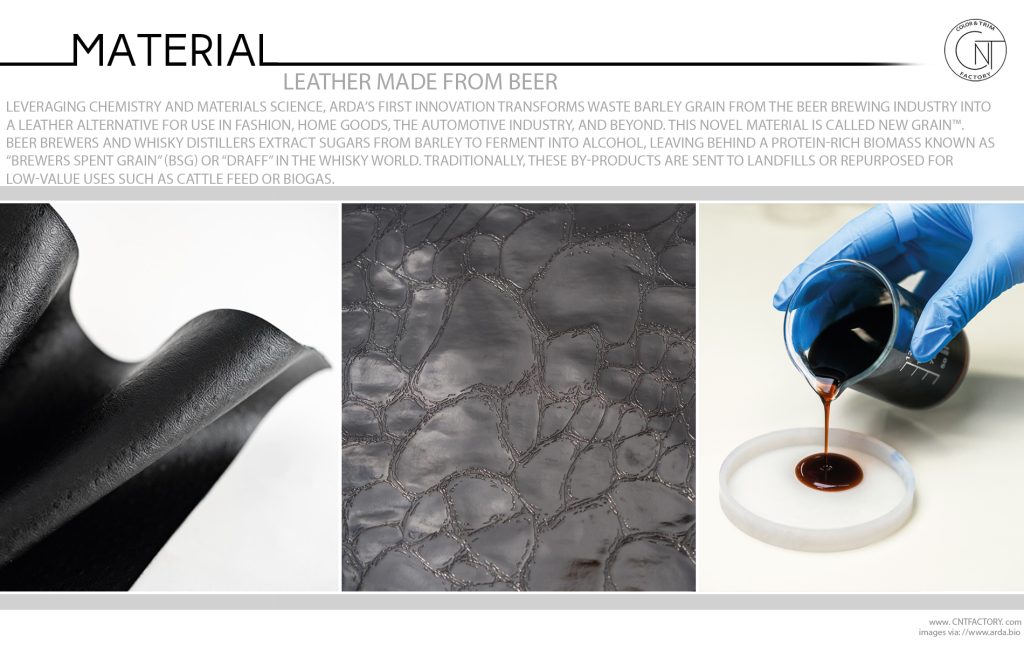

Leveraging chemistry and materials science, Arda’s first innovation transforms waste barley grain from the beer brewing industry into a leather alternative for use in fashion, home goods, the automotive industry, and beyond. This novel material is called New Grain™.

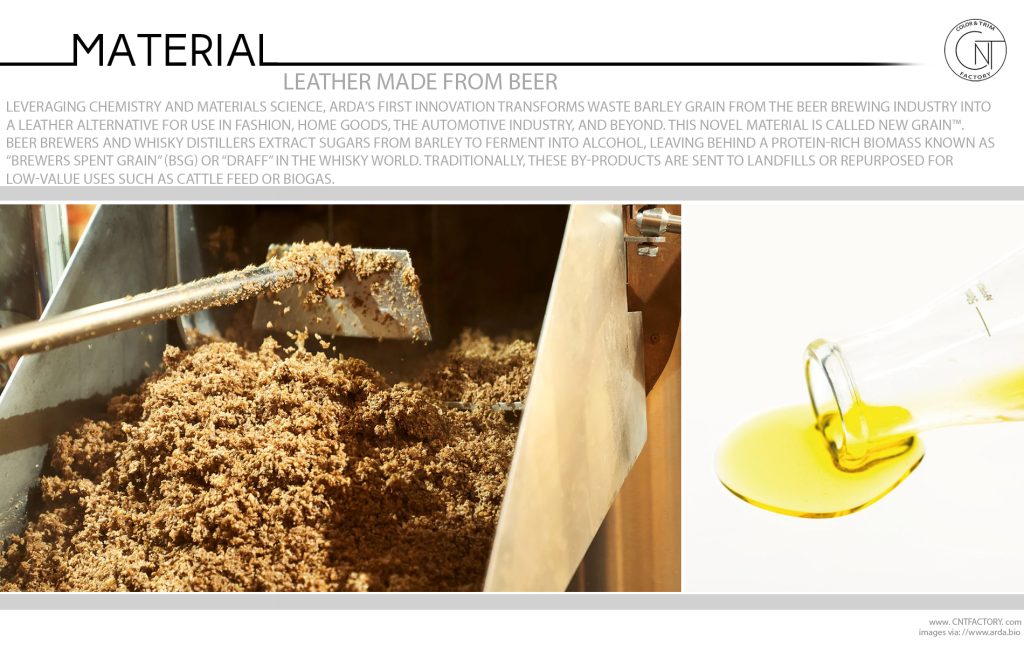

Beer brewers and whisky distillers extract sugars from barley to ferment into alcohol, leaving behind a protein-rich biomass known as “brewers spent grain” (BSG) or “draff” in the whisky world. Traditionally, these by-products are sent to landfills or repurposed for low-value uses such as cattle feed or biogas. Unlike many other leather-like materials that rely on polyurethane (PU) or other plastics for durability, flexibility, or protective coatings, New Grain™ stands apart. Through Arda’s breakthrough chemistry, proteins are used to replace plastics, replicating the complex fibrous structure of animal leather using plant-based proteins instead.

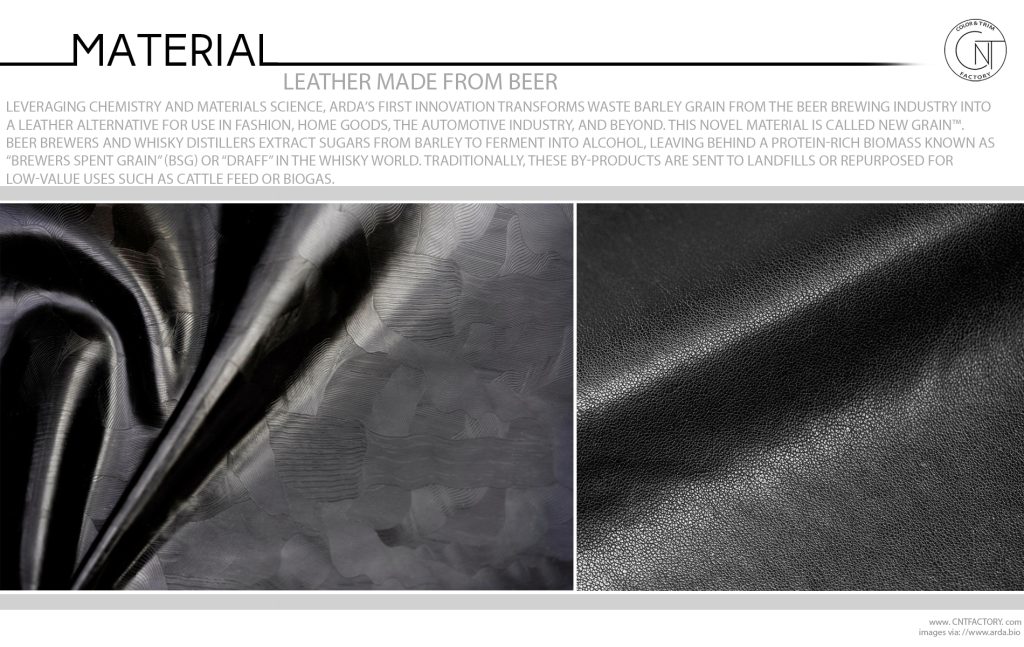

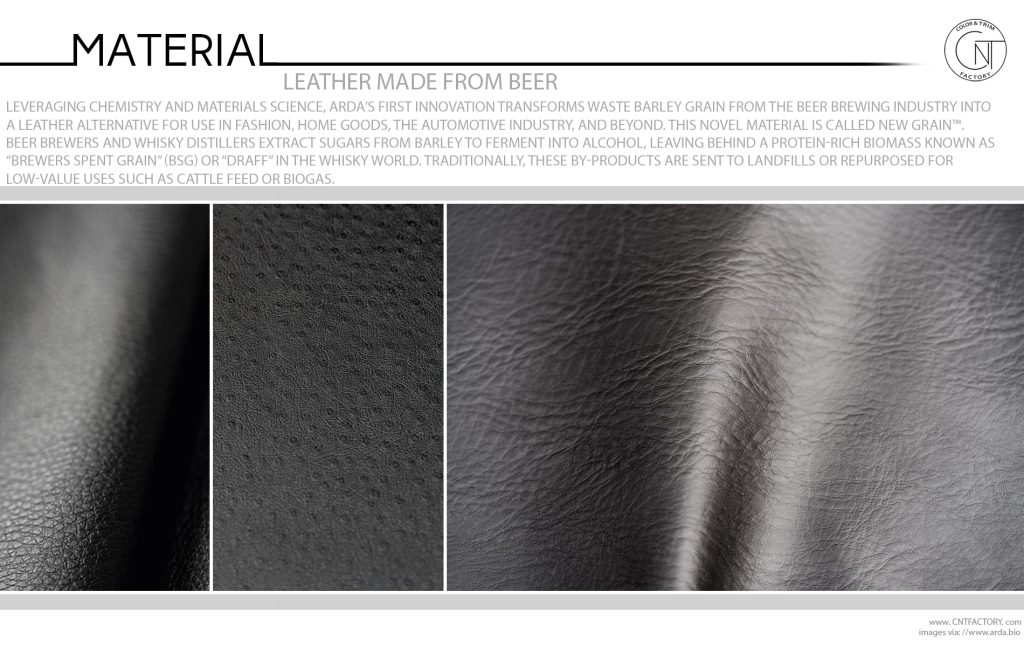

New Grain™ is being developed to meet diverse applications in fashion, automotive, and furniture upholstery, offering a high-performance material that excels in scalability, style, and functionality. It can be finished in similar ways to animal leather. Like traditional leather, New Grain™ is made of protein—only its source is plants.

One of New Grain’s greatest advantages is its versatility. The production process is highly customizable, allowing for variations in texture, thickness, and performance properties to suit specific needs.

Leather production is resource-intensive, and most current alternatives depend heavily on plastics. The chemical composition of waste grain is uniquely suited to be transformed into a material that captures many of leather’s desirable qualities and in some ways, surpasses them.