Sorry, this content is for members only.

Join To View ThisRelated Post: Zebra Glass

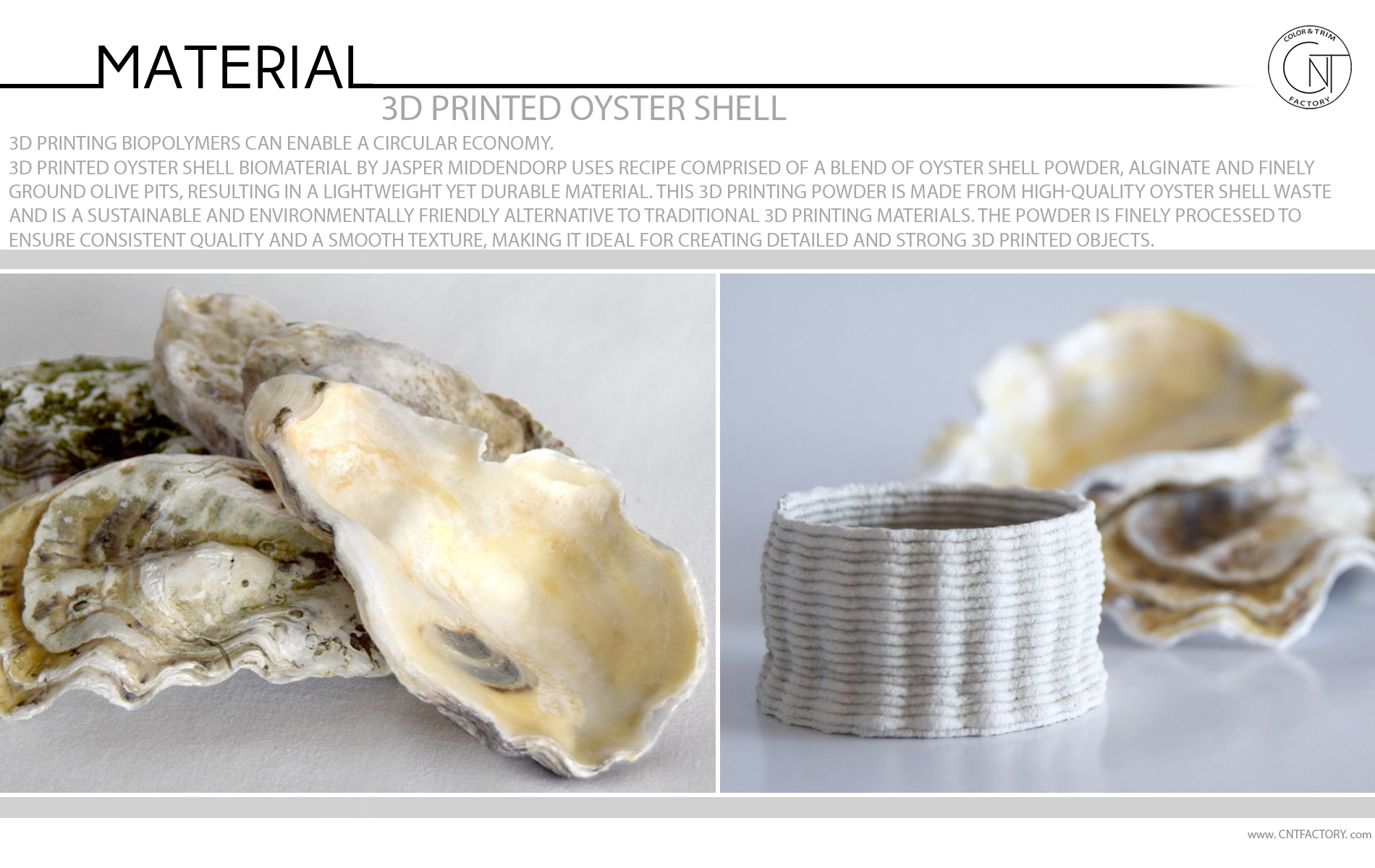

3D printing biopolymers can enable a circular economy.

3D Printed Oyster Shell biomaterial by Jasper Middendorp uses recipe comprised of a blend of oyster shell powder, alginate and finely ground olive pits, resulting in a lightweight yet durable material.

This 3D printing powder is made from high-quality oyster shell waste and is a sustainable and environmentally friendly alternative to traditional 3D printing materials. The powder is finely processed to ensure consistent quality and a smooth texture, making it ideal for creating detailed and strong 3D printed objects.

The materials, manufacturing and consumption habits of today are having a devastating impact on the world of tomorrow. We must transition to a circular approach where local materials drive design and nothing is wasted.

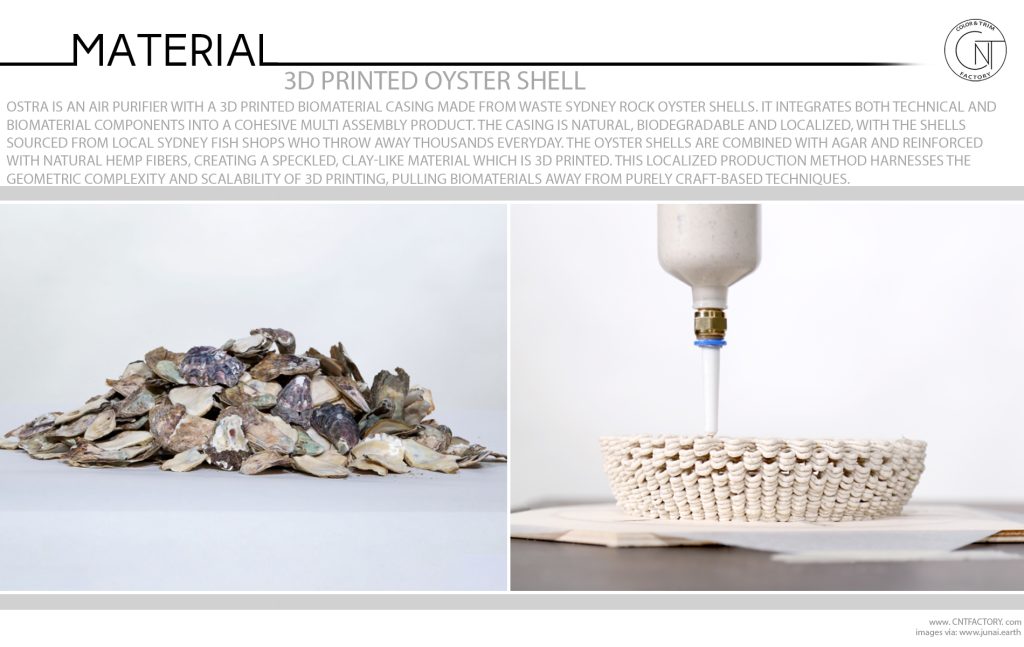

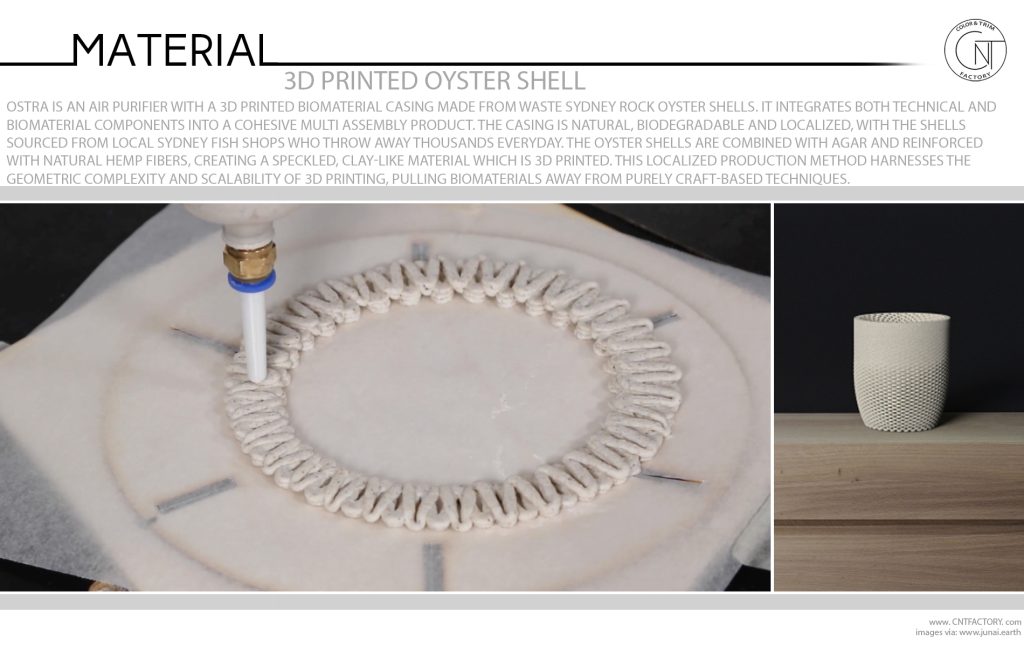

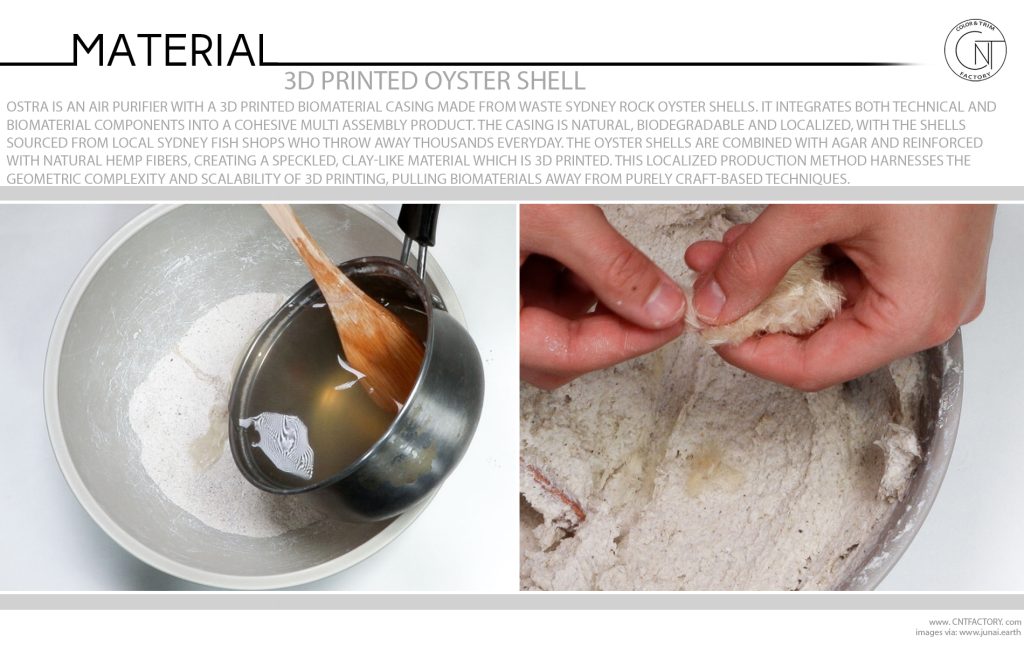

Ostra is an air purifier with a 3D printed biomaterial casing made from waste Sydney rock oyster shells. It integrates both technical and biomaterial components into a cohesive multi assembly product. The casing is natural, biodegradable and localized, with the shells sourced from local Sydney fish shops who throw away thousands everyday. The oyster shells are combined with agar and reinforced with natural hemp fibers, creating a speckled, clay-like material which is 3D printed. This localized production method harnesses the geometric complexity and scalability of 3D printing, pulling biomaterials away from purely craft-based techniques.